Recently, the new regulations on the "agricultural photovoltaic complementary" project issued by the Department of Agriculture and Rural Affairs of a certain province have attracted widespread attention in the industry. The new regulations clearly require that the unit area product shall not be less than 80% of the surrounding crop output value, and the area of agricultural unusable areas shall be less than 10%. This also means that agricultural photovoltaic projects will pay more attention to the balance between "light" and "agriculture", ensuring photovoltaic power generation while maximizing the utilization value of agricultural land.

In photovoltaic equipment, in addition to necessary facilities such as inverters, junction boxes, and cables, the land area occupied by the photovoltaic bracket pile foundation is large, and its surroundings are often not used for agricultural farming, resulting in a large area of agricultural unusable areas.

Hitting the pain point directly, flexible brackets have attracted much attention. According to calculations, if flexible brackets are used in agricultural photovoltaic projects, the area of agricultural unusable areas will account for only 0.59%. In addition, flexible brackets can also fit more complex terrains, and therefore have frequently appeared on the procurement lists of major central enterprises in recent years.

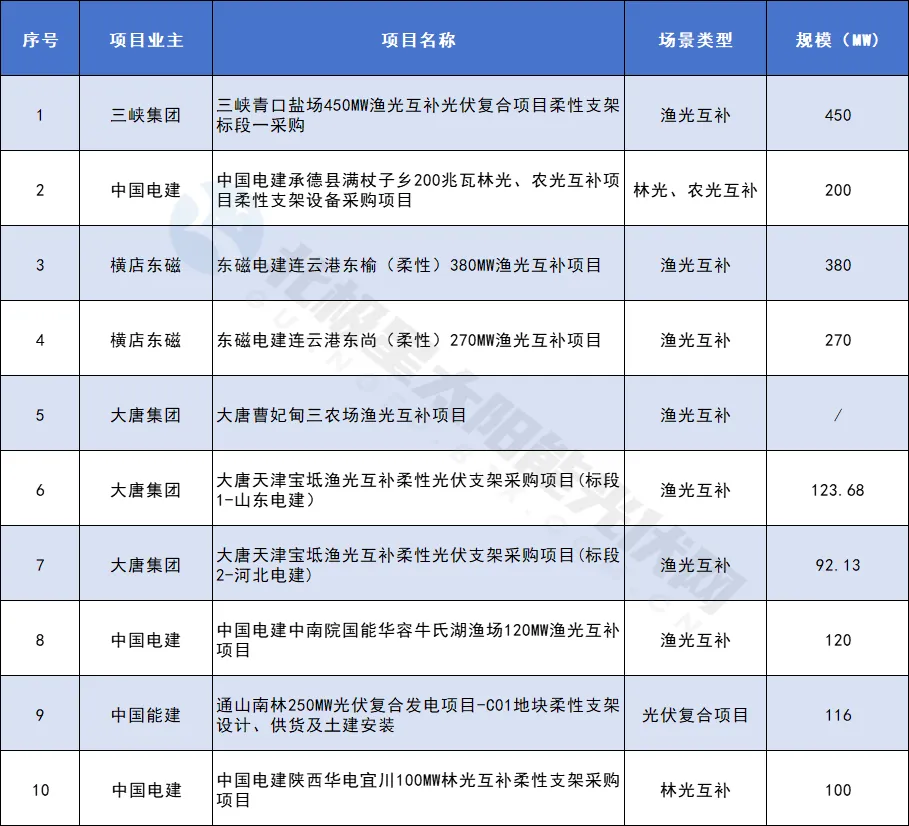

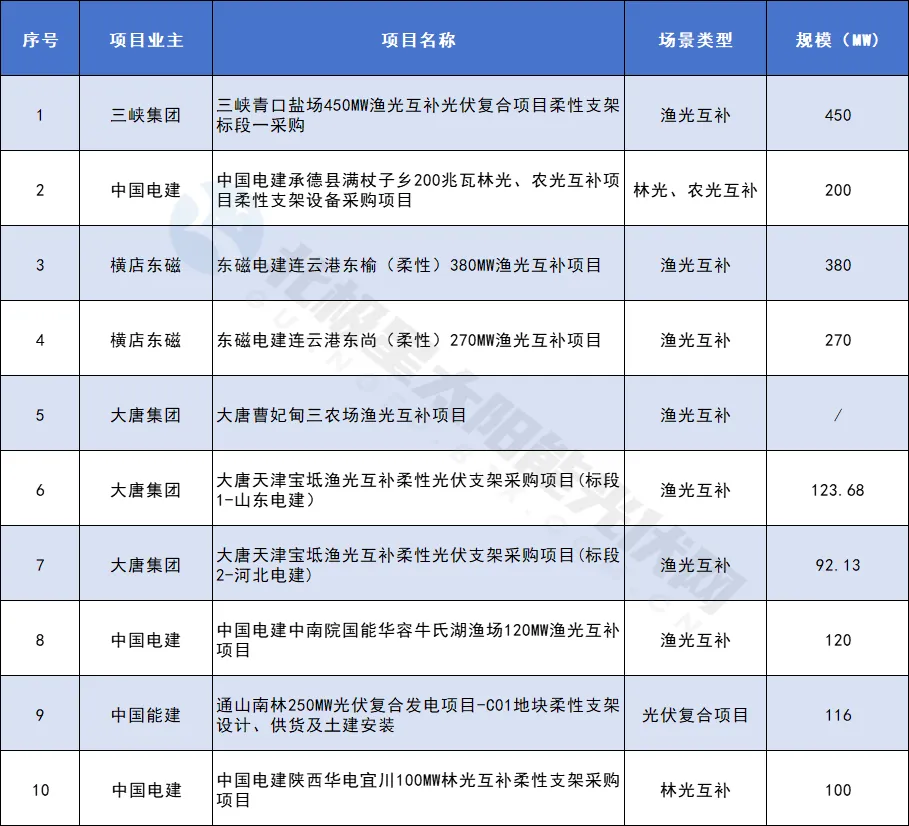

Recent public photovoltaic flexible bracket bidding list

Expanding photovoltaic application scenarios

After more than 20 years of photovoltaic development boom, “large, flat and wide” photovoltaic construction land has become increasingly scarce. Especially under multiple restrictions such as basic farmland red lines, ecological protection red lines and urban development boundary control lines, the land supply for photovoltaic projects has become increasingly scarce. The problem of deficiencies is becoming increasingly apparent.The relatively limited land resources have made the industry turn its attention to more challenging application scenarios such as mountains, hills, and tidal flats. And making full use of complex terrain is the specialty of flexible brackets.

Lanzhou Duanjiachuan Mountain Photovoltaic Power Generation ProjectIt is reported that compared with traditional fixed brackets, flexible brackets not only effectively solve the difficulties of difficult foundation construction, large foundation investment, long construction period, and difficult application of brackets when dealing with complex photovoltaic terrains such as mountains and hills, but also significantly reduce the number of Shadow blocking problems caused by uneven terrain ensure the efficiency and performance of photovoltaic power generation.

More importantly, the flexible brackets are carefully arranged according to the terrain and combined with the characteristics of flexible brackets having greater applicability to the applicable terrain, which significantly increases the installed capacity per unit area. Taking 1,000 acres of land as an example, traditional fixed brackets can only install about 60-70MW of components. With flexible brackets , the amount of panels can be increased to 80-90MW , achieving a capacity increase of about 30%. For some mountain projects, Because the red line is relatively regular, its capacity increase ratio can be as high as 40%-50%, and based on different scenarios, the flexible bracket can increase the power generation efficiency by 1.5%-3% compared with traditional fixed power generation.

At the same time, thanks to the "large span and high clearance" characteristics of the flexible bracket, mechanized construction in the space under the slab is almost unaffected, and can be well integrated with agriculture, forestry, fishery, etc., and can efficiently generate electricity in photovoltaic power stations. Compound utilization of land effectively increases the output value per unit land area and promotes the coordinated development of economic and ecological benefits.

In addition to maximizing land space utilization, the Yuguang complementary flexible photovoltaic support system has a small number of pile foundations, minimizing construction's environmental disturbance. Under the same conditions, compared with traditional fixed brackets, it can save steel and pile foundation costs, and is highly pre-assembled and can be erected quickly, saving a lot of installation time and construction costs, thereby greatly reducing the comprehensive investment cost of photovoltaic power stations.Three Leaps in Product StructureAs an innovative product in the photovoltaic field, flexible bracket technology has gone through three iterations. The

initial generation of flexible bracket design mainly revolves around a single row of components installed horizontally on two steel cables . However, because it completely relies on steel wire ropes for support, it does not have any wind resistance or vibration reduction measures. Based on the characteristics of the cable structure that wind vibration will occur, The durability and reliability of photovoltaic power plant systems cannot be guaranteed.

Subsequently, the second-generation flexible bracket was unveiled with a structure in which modules are installed vertically in a single row on two steel cables . It uses steel strands as supports and ensures the stability and stability of photovoltaic modules under external loads by applying sufficient prestress. Security. This innovative design significantly improved the stability and safety of photovoltaic arrays and quickly became widely used in photovoltaic power station construction.

However, with the in-depth application of technology, second-generation products have also exposed some technical challenges and potential risks. For example, the out-of-plane torsional stiffness of a double-cable load-bearing structure is relatively small, which may affect the overall structural stability under high wind load conditions.

As a result, the third generation of products came into being, such as the ATEC Qingtianqing cable net flexible bracket of Shenzhen Antaike, the first national high-tech enterprise in the industry , which adopts the design principle of "top-loaded suspension bridge" and passes through the triangle The bracing provides vertical load support, and the single-row components are connected into a whole in the north and south directions by adding lateral stabilizing trusses (cables). The lateral stabilizing truss (cable) frame consists of steel beams (cables) running through the top and bottom to form a lateral stabilizing system, which significantly improves the stability of the system under the action of wind.

Industry insiders pointed out that the design of the third-generation flexible bracket cleverly avoids possible damage to the system caused by tremors caused by strong winds, and successfully solves the problems of difficult-to-control deformation of the first two generations of products and hidden cracks in components caused by twisting and collisions. , truly paves the way for the large-scale application of flexible stents.

At present, the new generation of ATEC Qingtianqing cable net flexible bracket has passed a variety of extreme working conditions tests and can be used in large spans of 30 to 45 meters.Under such circumstances, it is ensured that the components will not experience destructive wind-induced vibrations. At the same time, a large amount of application experience has been accumulated to ensure that the flexible support columns can be flexibly set up without being affected by slope, angle, terrain, ground height and other issues. The height range of ATEC Qingtianqing Cable Net Flexible Support is 1 to 8 meters . It can realize a variety of application scenarios such as "fishery-light complementation", "agriculture-light complementation", "forest-light complementation", "pastoral-light complementation" without destroying the original terrain or affecting the original use function of the land, thereby greatly expanding the land use field of photovoltaics and solving the problem that some scenarios are not suitable for or cannot be used for photovoltaic power station construction.ATEC's Qingtianqing cable net flexible support technology has overcome the technical difficulties of large slopes and large spans. In the project in Xiaomengtong Town, Yongde County, Yunnan, the Shenzhen Antaike team successfully overcame the difficulties of complex terrain, steep slopes, and rugged mountain roads, and successfully erected the ATEC Qingtianqing cable net flexible support on a cliff with an angle of more than 60 degrees. Similarly, in the Sayongshan photovoltaic power station project with an altitude of more than 3,000 meters and a slope of more than 35 degrees, the Shenzhen Antaike team continued to explore and provided a model solution for the mountain flexible photovoltaic project with the highest altitude, largest slope, and largest span in the country at that time , and successfully connected to the grid for power generation as scheduled.

The unique and significant advantages of ATEC's Qingtian Qing cable net flexible bracket have won wide recognition in the market. Since 2024, ATEC's Qingtian Qingcable Net flexible bracket can be seen in the 450MW fishery and photovoltaic complementary project of the Three Gorges Qingkou Salt Field, the 650MW fishery and photovoltaic complementary project of DMC Electric in Lianyungang, and the Datang Tianjin Baodi fishery and photovoltaic complementary project... Continuously undertaking large-volume flexible projects not only reflects the continuous expansion of the application scale of flexible bracket technology in major projects, but also demonstrates the strong market penetration and adaptability of ATEC Qingtianqing Cable Net's flexible brackets.

The latest market data also confirms this. In the first half of 2024, Shenzhen Antaike's flexible bracket shipments exceeded 2GW, with a market share of more than 40%. Its projects are spread across many provinces including Yunnan, Jiangsu, Gansu, Zhejiang, and Guangdong.

Breaking through the "controversy"

Flexible brackets are gradually gaining market recognition. However, the current flexible bracket technology is in a critical stage of continuous improvement and revision of industry standards. Many companies have flocked into this field, resulting in a complex situation in the market where first-generation, second-generation and third-generation products are mixed, various structural schemes coexist, and patent infringements occur from time to time . This not only poses a serious threat to the safety of power stations, but also hinders the healthy development of the industry.Industry insiders pointed out that even the third-generation products have unreasonable structural designs and solutions that have not been verified by wind tunnel tests and simulation tests . Once these brackets fail, their non-reshapeable nature makes remedial measures extremely limited, resulting in extremely heavy losses.For large-span structures such as flexible supports, strong winds are the main cause of support structure damage. my country has a vast territory, diverse climates, frequent strong winds and complex causes. Photovoltaic power stations inevitably face the challenge of strong winds. According to a report by China Meteorological News, the number of strong wind days in the Qinghai-Tibet Plateau is as high as more than 75 days per year, and the number of strong wind days in central and northern Inner Mongolia and northwestern Xinjiang is also more than 50 days. The southeast coast and its islands are also frequently affected by strong winds, with more than 50 days per year. These areas are also often affected by Pacific air currents and suffer from extreme weather such as typhoons.Since the beginning of this year, photovoltaic power stations in Yunnan, Shanxi, Shandong and other provinces have been hit by strong winds, resulting in component distortion, collisions and even collapse of supports in some power stations equipped with flexible supports.Of course, there are also projects that have performed well in the test of strong winds, such as Guangdong Energy's photovoltaic composite project in Gongguan Town, Maoming Maonan . The project is located in an area where typhoons are frequent and directly impacted. In 2023, when facing the severe challenges of the two super typhoons "Sura" and "Haikui", the core parts of its flexible support system, such as the foundation, steel structure, and main cable, were all as stable as before, successfully withstanding the impact of the 14-level typhoon . The project used the ATEC Qingtianqing Cable Net Flexible Support provided by Shenzhen Antaike.

It is understood that Shenzhen Antaike has conducted rigorous wind tunnel tests on each model of its products in response to high wind pressure environments to ensure the stability of the flexible bracket component structure in strong wind environments. At the same time, Shenzhen Antaike has worked closely with Hunan University, Central South University, and well-known wind tunnel laboratories and wind engineering research centers at home and abroad to conduct in-depth rigid pressure test, dynamic parameter analysis, and aeroelastic stability research on photovoltaic support system series products. At present, Shenzhen Antaike's R&D investment in this field has reached nearly 30 million yuan. Through a series of wind tunnel experiments, the accumulation of field and experimental data, and big data analysis of sample frame tests, it has provided a solid and reliable scientific basis for the continuous optimization and upgrading of the bracket.

In addition to wind loads, equipment corrosion protection is also a focus of many owners. Flexible brackets are mostly used in harsh environmental areas such as mountains, deserts, and water surfaces, and the degree of corrosion they endure is far greater than that of general environments. Therefore, during the design and production phase of Antaike Qingtian Cable Net Flexible Bracket, the main structural components such as suspension cables, anchors, and clamps were precisely treated with anti-corrosion treatment. In environments with high anti-corrosion requirements such as surface fish ponds and coastal tidal flats, an innovative method of wrapping the outside with a polyvinyl chloride sheath and filling the inside with epoxy resin is used to improve the corrosion resistance and durability of the bracket.

The 100MW fishery-photovoltaic complementary project in Chenjia Town, Chongming is a typical case. The project is adjacent to the East China Sea in the east and the Yangtze River in the south, which places extremely high demands on the corrosion resistance of the support. The Shenzhen Antaike team fully considered the local environment, adopted PHC pipe pile structure as the column, combined with hot-dip galvanizing anti-corrosion technology, and finely adjusted the raw materials and hot-dip galvanizing parameters, successfully meeting the anti-corrosion requirements and providing long-term and stable protection for the project.

A series of project cases have proved the necessity and reliability of the new generation of flexible brackets in complex scenarios. As domestic land resources become increasingly scarce, the deserts and Gobi in the northwest, the mountains and hills in the southwest, and the tidal flats in the southeast coastal areas are gradually becoming the top priority for ground photovoltaic construction. Undoubtedly, flexible brackets are ushering in the spring of development.

Source: Polaris Solar Photovoltaic Network

Author: Sangsang