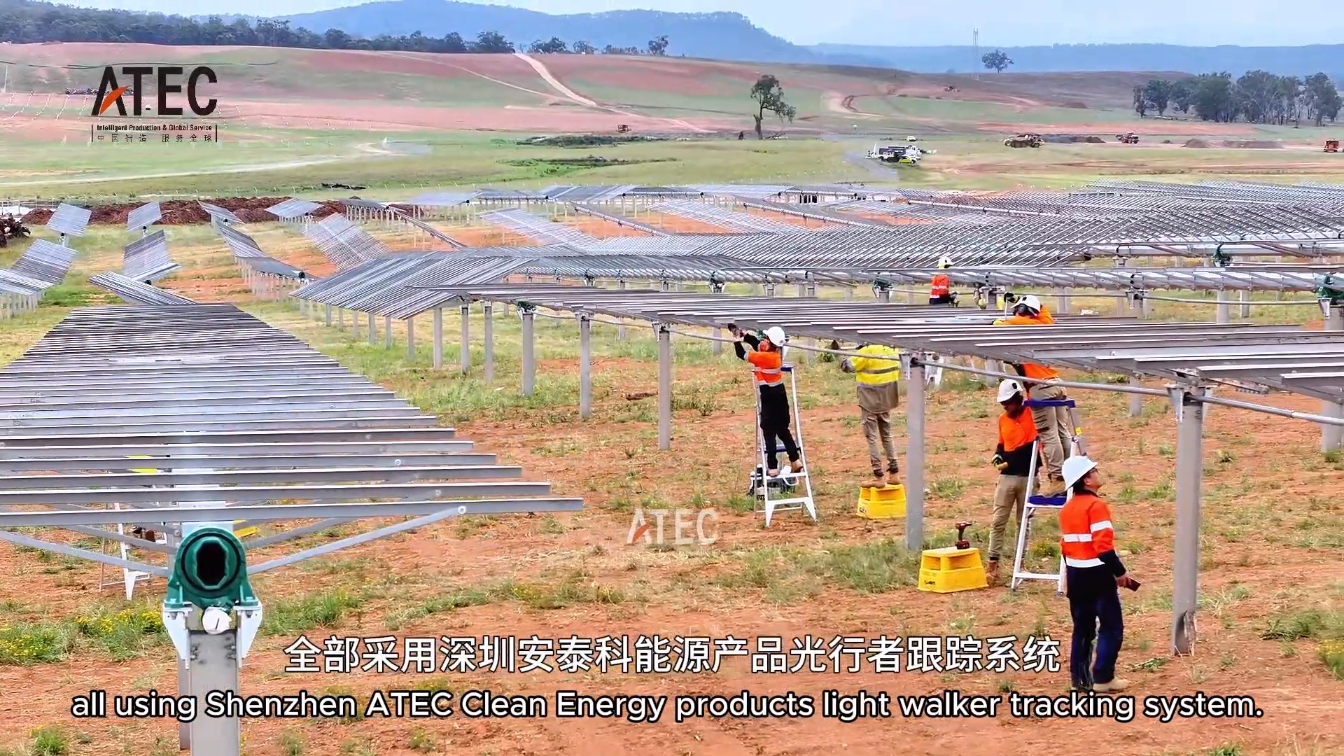

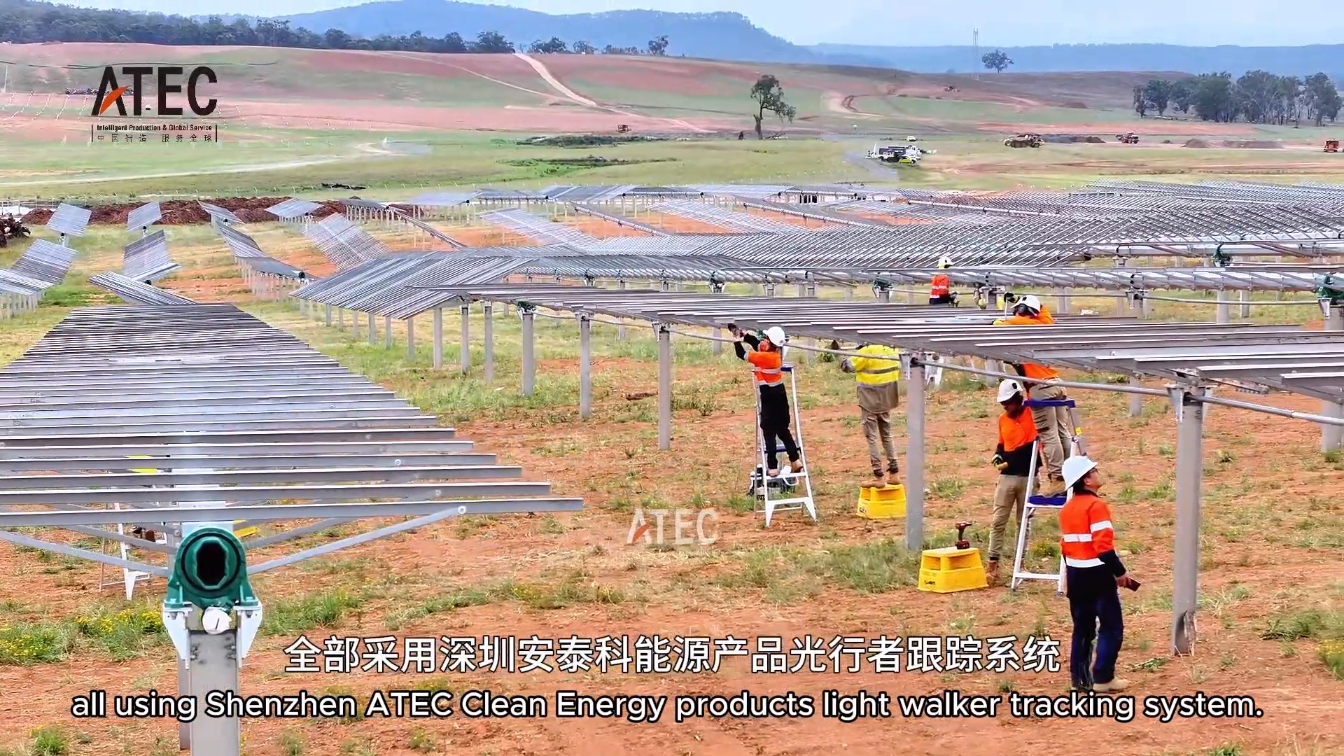

This is southeastern Australia, with four distinct seasons, sunny days, 240 days of sunshine each year, and an average of nearly 7 hours of sunshine per day, making it an ideal place to develop photovoltaics.

The project has an installed capacity of 345MW , and all of it uses Shenzhen Antaike Energy's ATR-06 tracking bracket.

Two major innovations: the first octagonal shaft design

The ATR-06 tracking bracket was designed by the Shenzhen Antaike team based on the static, dynamic and aeroelastic reports provided by CPP, an authoritative American wind tunnel consulting firm. It has overcome the difficulties in international mainstream specifications, passed the wind tunnel test, and can more accurately calculate the bending moment and torque acting on the photovoltaic bracket.

Two major innovations: integrated self-created reverse tracking algorithm

The integrated self-created reverse tracking algorithm can effectively avoid the front and rear rows of the bracket from being blocked. By adding sensors and other devices to monitor real-time solar radiation values, temperature and humidity, wind speed and direction, and module temperature, the position, inclination, and working status of the photovoltaic modules can be automatically adjusted to maximize power generation efficiency.

Achieve three increases and three decreases

Improve power generation revenue. Check the tracking angle throughout the day to ensure the operation accuracy of the bracket, and always supervise the site to ensure the subsequent tracking accuracy of the bracket.

Improve wind resistance. In terms of wind resistance strategy, a small angle is used as a protection angle to reduce the wind load on the bracket. At the same time, the stability is verified through aeroelastic tests in a wind tunnel to ensure that the bracket is safe and stable under the designed wind speed.Improve the applicable scene. It can be used on sloped terrain within a certain range without leveling the site.

Reduce costs. Under the same wind load level, the "rectangular octagon" can save 10%-20% of the material consumption.Reduce energy consumption. By using a highly energy-saving system design, the overall daily operating energy consumption is less than 0.063kWh.Reduce working hours. When conditions are right, you can avoid high-altitude work. The factory is highly prefabricated and debugging is carried out in sub-array units, with a speed of up to 4-5MW/day/person . At the same time, remote monitoring is used to reduce tracking downtime caused by bracket failure.

The ATR-06 tracking bracket can increase power generation by more than 10% compared with traditional fixed brackets . After the project is completed, it will be able to provide renewable clean energy to 300,000 households every day.

Shenzhen Antaike Energy has presence in nearly 20 countries across five continents . In the future, it will always uphold the concept of win-win cooperation, continue to work hand in hand with its partners, forge ahead and move towards a new stage of development.